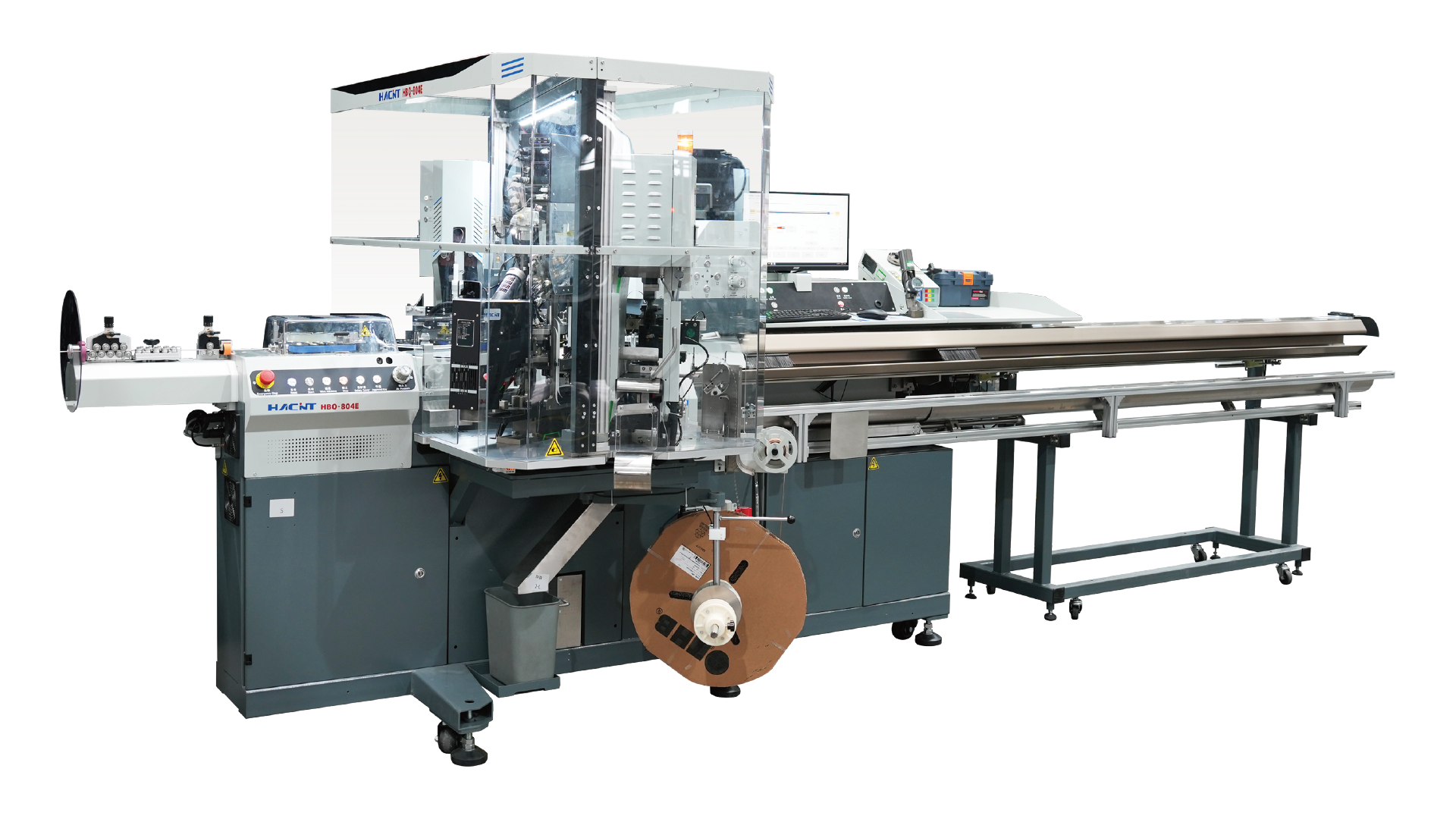

HBQ-804E automatic crimping machine is a brand-new type independently developed by Hacint for the wire harness industry. It features a six-station flexible platform, and in addition to the crimping station, it can be equipped with workstations with different functions such as sealing workstations, visual inspection workstations, and pressure module workstations can be freely combined. The equipment is driven by a servo system with new technology and is equipped with a highly integrated and lightweight swing - arm structure, a specially designed dual - channel cutter, a multi - function button panel and other new designs, making the equipment powerful and suitable for a wide range of processes.

Caractristiques

● High quality: Equipped with a standard pressure management device to detect defective products; ● Flexibility: It can process special processes based on platform selection and module configuration; ● User-friendly: Hacint family-style design interface is simple and easy to learn; ● Easy to operate: No need to raise the protective cover for debugging and positioning of the multi-function button board; ● Quick-change type: The dual-channel cutter does not require frequent blade replacement; ● Wide range: The compatibility design allows for processing a wide range of wire diameters.

Pourquoi choisir ce modele ?

Le HBQ-804E Automatic Crimping Machine fait partie de la gamme fully automatic crimping machine concue pour accompagner les equipes industrielles en production quotidienne. Sa conception robuste assure une performance reguliere sans multiplier les operations de maintenance.

Ce modele est disponible sur devis afin d'apporter la configuration la plus pertinente pour votre cahier des charges. Rupture de stock pour garantir un approvisionnement fiable et rapide.

Megaindus accompagne chaque projet : analyse, parametrage, mise en service et transfert de competences. Vous beneficiez ainsi d'un referent dedie et d'une documentation claire pour securiser l'exploitation du HBQ-804E Automatic Crimping Machine.

Points cles a retenir

- Type : HBQ-804E

- Length Range : 50~200000mm

- Length Accuracy : ±(1mm +0.2% *L)

- Stripping Length : 0.1~29.5mm

- Stripping Accuracy : ±0.5mm

- Wire Cross Sections : 0.13~6mm²

Ce tableau resume les principaux parametres du HBQ-804E Automatic Crimping Machine et facilite la comparaison avec d'autres references disponibles.

| Caract\u00E9ristique | HBQ-804E Automatic Crimping Machine | HBQ-804-03A Wire Prefeeder | HBQ-054 Stripping and Plugging Detection System | FSA-001E Sealing Module |

|---|---|---|---|---|

| Type | HBQ-804E | - | - | - |

| Length Range | 50~200000mm | - | - | - |

| Length Accuracy | ±(1mm +0.2% *L) | - | - | - |

| Stripping Length | 0.1~29.5mm | - | - | - |

| Stripping Accuracy | ±0.5mm | - | - | - |

| Wire Cross Sections | 0.13~6mm² | - | - | - |

| Wire Feed Speed | 12m/s(max) | - | - | - |

| Noise Level | 80dB(Without crimping) | - | - | - |

| Air Supply | 5~6Bar | - | - | - |

| Air Consumption | 5.5~10m³/h | - | - | - |

| Temperature | 5~+40℃ | - | - | - |

| Crimp Force | 20kN | - | - | - |

| Crimp Stoke | 30mm or 40mm | - | - | - |

| Productivity | 4400pcs/h( 1000mm long double-ended crimping for 0.5mm² wire ) | - | - | - |

| Power supply | AC380V/50Hz | - | - | - |

| Power | 4kW(Standard configuration) | - | - | - |

| Overall Dimensions | L3800×W1550×H1900mm(Two-meter wire winder) | - | - | - |

| Weight | 1200kg(Standard configuration) | - | - | - |

| Optional Accessories | Pre-feeding wire machine , double straightener, double terminal material tray, terminal microscope, inkjet printing module, laser marking module, seal loading module, servo crimping machine (20kN or 40kN), wire combining module, rotary stripping module, tubular terminal module, tensile testing machine, constant pressure height measurement, gyrating ruler measurement, wire replacement detection, wire joint detection, wire skin breakage detection, wire take-up machine: 4m, 6m, 8m, 12m, 20m | - | - | - |